Solvent-based Recycling Process for Polypropylene Products

N. Kizildag, A. Tufani, B. Sevinis, S. Guclu, B. Dizman, Y. Menceloglu, S. UnalIntegrated Manufacturing Technologies Research and Application Center, Sabanci UniversityTuzla, 34956, Istanbul, Turkey (serkanunal@sabanciuniv.edu)

ABSTRACT

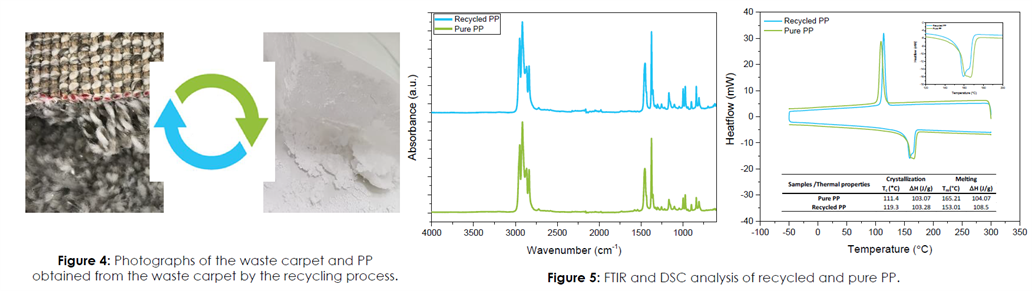

Polypropylene (PP) is used in a wide variety of products, including automobile interiors, packaging, electronics, construction materials, carpets and other home furnishings. Very short life and low recycling rates of PP products make it a substantial contributor to the contamination of the environment. The aim of this study was to develop a solvent-based recycling process for PP products using polypropylene containing waste carpet as the starting material. Virgin grade PP was obtained, which was identical to raw PP according to FTIR and DSC analysis. The new recycling process is expected to reduce the reliance of PP production on fossil resources and to avoid the end-of-life PP products pollute the environment.

INTRODUCTION

- Plastic products are widely present on the market in a lot of applications.

- Exceptional rise in the use of the plastic products due to their versatility, excellent properties and availability in large quantities with low costs [1].

- Polypropylene (PP) is the world’s second most widely used commodity polymer (after polyethylene).

- The global PP market was valued more than $80 billion in 2017, totaling approximately 23% of the entire plastics market and expected to reach $133billion by 2023 [2].

- Only 1% of these PP products are recycled [3].

- Recycling technologies used in the recycling of PP are mostly mechanical and/or thermal, which generally result in low quality products containing contaminants such as pigments and degraded components [4,5].

EXPERIMENTAL

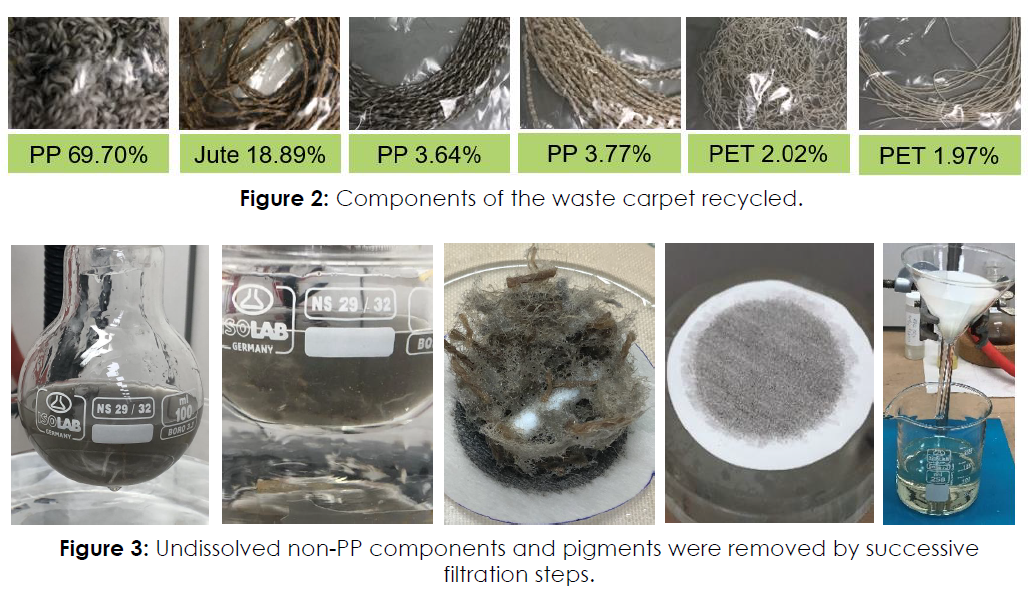

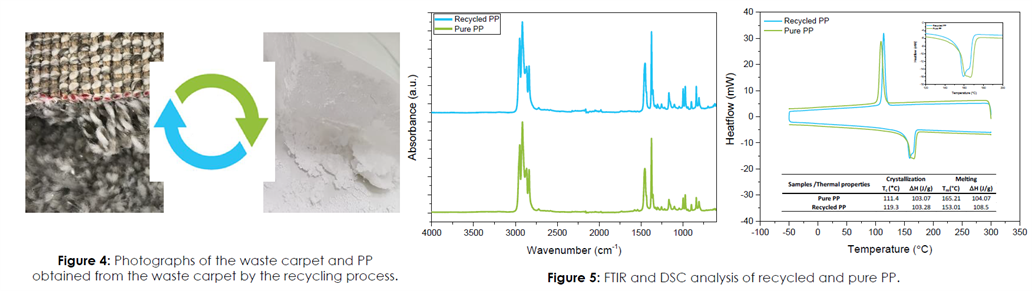

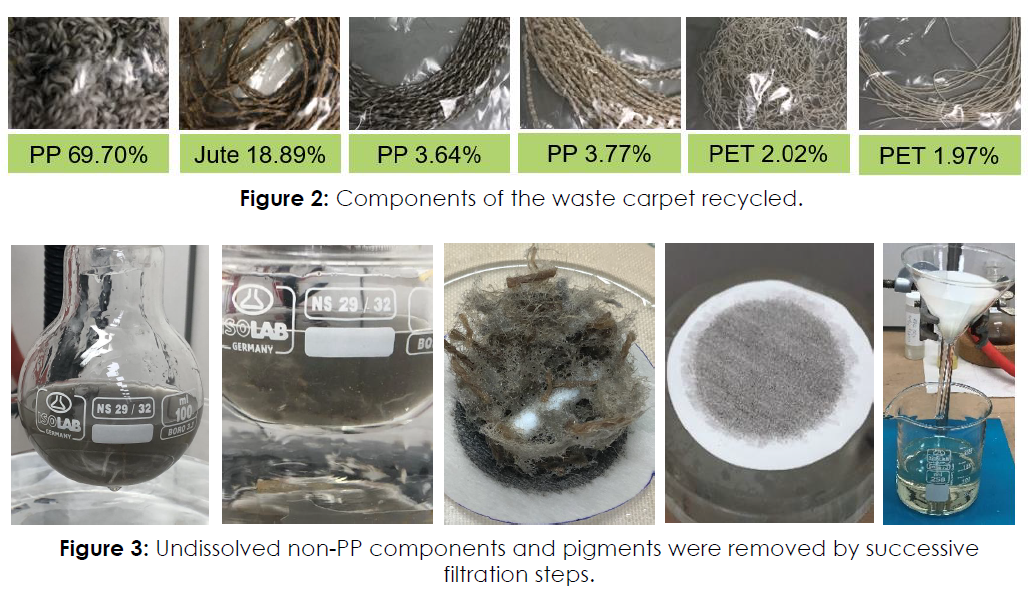

Waste carpet materials were used as feedstock. The waste carpet sample, consisting of 77% PP, 19% jute and 4% polyester, was chopped and mixed into the proprietary solvent, which was specifically designed for high solubility of PP. The mixture was stirred magnetically at 140°C under reflux until the PP fibers were dissolved. After successive filtration steps performed to remove the undissolved non-PP components and the pigments, the filtered solution was poured into isopropanol for precipitation. While precipitated PP was separated by filtration from the solvent/isopropanol mixture and dried in an oven; the proprietary solvent was recovered by rotary evaporator. FTIR and DSC was used to for the characterization of recycled PP.

RESULTS

CONCLUSIONS

The solvent-based recycling process was proved to be useful in the recycling of PP. It could be possible to obtain virgin grade PP, which was identical to raw PP according to FTIR and DSC analysis. The new recycling process is expected to reduce the reliance of PP production on fossil resources and pollution of the environment by the end-of-life PP products.

Download ISOPREP Poster HERE.

References

[1] Ben Said, A., Guinot, C., Ruiz, J.C., Grandjean, A.,Dole, P. Joly, C., Chalamet, Y. (2016) Supercritical CO2 extraction ofcontaminants from polypropylene intended for food contact: Effects of contaminant molecular structure and processing parameters, Journal of Supercritical Fluids, 110, 22–31. [2] LeBlanc, R., An Overview of Polypropylene Recycling, https://www.thebalancesmb.com/an-overview-of-polypropylene-recycling-2877863, Accessed 13/05/2019. [3] https://purecycletech.com/2019/03/purecycle-technologies-partners-with-milliken-nestle-to-accelerate-revolutionary-plastics-recycling,Accessed 13/05/2019 [4] La Mantia, F. P. (2004), Polymer Mechanical Recycling: Downcycling or Upcycling?, Progress in Rubber, Plastics and Recycling Technology, 20 (1), 11–24. [5] Thomas, G. P., Recycling of Polyppropyylene (PP), https://azocleantech.com/. Accessed 13/05/2019.