Polypropylene (PP) is the most widely used commodity plastic globally. Annual global production of polypropylene amounted to 56 million MT in 2018, production is expected to increase to 88 MMT by 2026 with a value of almost $160 billion US [1]. Polypropylene is widely used in many familiar products including food and beverage packaging, carpets, electronics components, automobile interiors, pipelines for water and the oil & gas sector, home furnishings and even bank notes.

However, polypropylene is derived from a non-renewable resource and is a substantial contributor to the non-biodegradable plastic waste found polluting both land and sea.

A significant amount of polypropylene waste comes from used carpets. In the UK alone approximately 400,000 tonnes of carpet waste are sent to landfill every year [2]. Sustainable recycling and management of polypropylene waste will provide the opportunity to reduce the waste of valuable resources, the fossil fuel usage, greenhouse gas emissions and consequently reduce the landfilling.

The ISOPREP project offers an innovative solution to the recovery of virgin-like polypropylene from waste products, and thus reduce the amount of polypropylene that is disposed of and produced.

The objectives of the ISOPREP project are:

◾ To design and develop a pilot plant for the solvent-based recycling of end-of-life polypropylene using a waste carpet feedstock.

◾ To produce virgin quality polypropylene that has a similar performance to commercial polypropylene.

◾ To produce virgin quality polypropylene that is cost competitive with commercial polypropylene manufactured from fossil fuel resources.

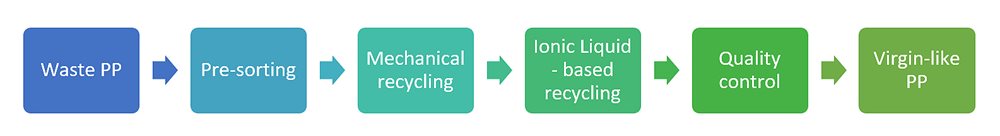

The ISOPREP project is developing a recycling process that combines both mechanical and chemical recycling. This combinational approach allows us to take end of life carpet and extract virgin quality polypropylene that is suitable for high end use.

The mechanical recycling step involves washing, separation of the carpet backing and then shredding and grinding the carpet to smaller fragments. In the chemical recycling step, an environmentally friendly ionic liquid is used to dissolve the polypropylene and separate it from dyes, additives and other contaminants.

Ionic liquids (ILs) are salts that exist as liquid at temperatures below 100°C. They consist of combination of organic/inorganic anions and organic cations. In contrast to the conventional organic solvents, ILs are considered as environmental reaction media owing to their distinctive chemical and physical properties. They are held together by strong ionic bonds making them less volatile, thermally stable, and non-flammable, offering lower risk of atmospheric contamination. Another significant advantage of ILs is their great recyclability; therefore, ILs containing dissolved catalysts are frequently used in reaction cycles. In addition, the positively and negatively charged ions in the ILs can be functionalised using a range of complex chemistries. This enables fine tuning of their physical and chemical properties to a remarkable degree, allowing solvents to be designed to suit specific process parameters.

An in-house synthesized ammonium-based IL has been developed that optimises the dissolution of polypropylene. It has been highly tuned to dissolve only PP whilst not dissolving any other chemical species at the operating temperature of the process. The concentration of the IL and the mechanical stirring systems have been optimised to achieve the most rapid dissolution. The IL used in the ISOPREP process has a specific dissolution properties meaning that it can selectively dissolve the polypropylene and separate this from other (non-PP) waste carpet fibres. A filtration system separates the solid waste at the end of the process. This facilitates the recovery of very high purity grade polypropylene that cannot be achieved using existing recycling techniques.

The ISOPREP process is currently run at in laboratory scale facility which has a capacity of several litres. The project is currently building a scaled-up pilot plant capable of recycling a tonne of carpet waste per day. This pilot plant will commence operation in March 2022.

◾ Extraction of virgin quality polypropylene suitable for high end use

◾ Reduced need for production of polypropylene from fossil fuels

◾ Provide a true recycling capability for polypropylene waste enabling a circular economic approach to be realised

◾ Sustainable and alternative method for plastic production.

ISOPREP will reclaim pure resin from post-consumer polypropylene waste with the quality suitable for high-end, added-value applications.

◾ Decreased utilisation of fossil fuels in the process industry.

Manufacturing carpets from 100% recycled polypropylene will reduce the usage of fossil fuels as a primary feedstock

◾ Decrease in CO2 emissions.

Increased recycling of carpets will reduce greenhouse emissions associated with production of virgin PP from fossil fuels as well as landfilling.

◾ Reduction in plastic waste being sent to the landfill.

The ISOPREP project uses waste polypropylene as a feedstock for its process. This allows for end-of-life polypropylene products being recycled rather than ending up in the landfills.

◾ Development of learning resources and expansion in the sustainable industry sector.

ISOPREP will result in extensive cross-cutting across multiple sectors and will provide training of employees in sustainable technologies.

![]() The ISOPREP project (Grant number 820787) is funded by the European Union’s Horizon 2020 research and innovation programme

The ISOPREP project (Grant number 820787) is funded by the European Union’s Horizon 2020 research and innovation programme